Cartoning

That box of candy you buy at the movies? The health test you take in the privacy of your home? The medicine that’s easy to grab off the shelf and throw in your cart? Cartoning helps make it happen. The automated cartoning process in packaging has many components and several steps. From forming the box to adding products and literature to sealing the carton, this type of secondary packaging is ideal for making your product shelf-friendly and retail-ready.

Products Ideal for Cartoning

Personal

care

Household Products

Home

Test Kits

Medicine and Vitamins

Beauty and Cosmetics

Confectionery

Office

Products

How does a cartoning machine work?

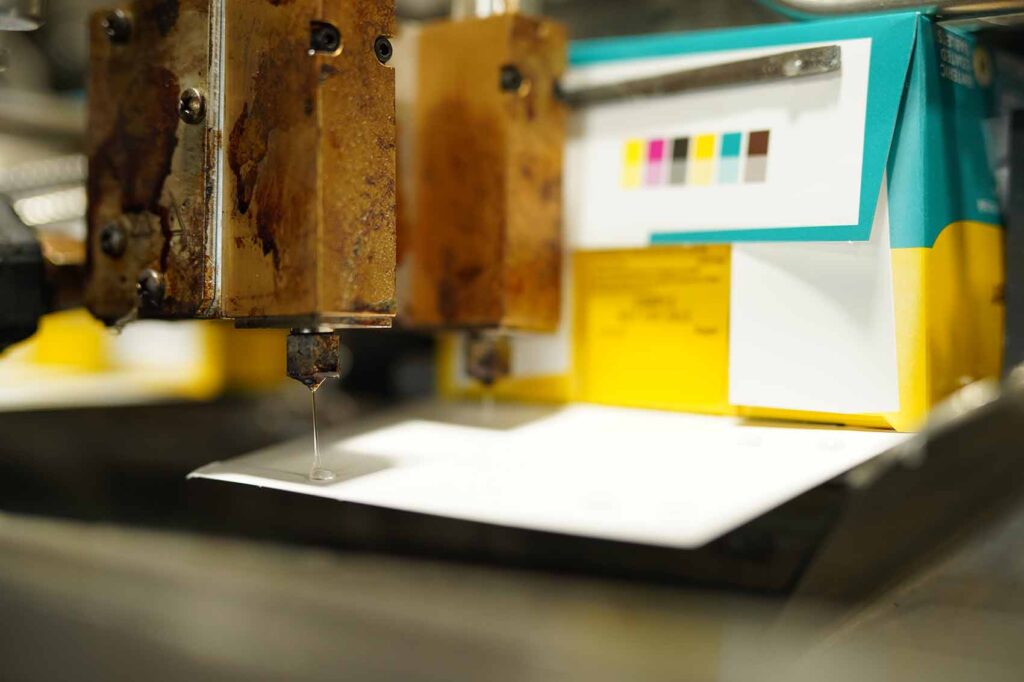

A cartoning machine (or cartoner) forms the cartons that hold your product and are opened by the end user. There are two types of cartoning machines, depending on how the carton is fed through the machine: vertical and horizontal. Along with several other elements, pressurized air is often a component of a cartoner. It can be used to push products into the open carton, push faulty items out of the production line, and more.

The cartoning process starts by taking the flat, printed carton (called a blank) and pulling it apart to form a box. The bottom tabs are folded inward and the bottom and sides are sealed. The box is filled, the top tabs are folded in, and the box is sealed shut. An expiration or “best by” date is laser-printed onto the box before the finished cartons are placed in boxes for shipping.

Many companies rely solely on hand-packing cartons, which is a slow process requiring multiple people working on the same line, which increases personnel and therefore production costs. At McNerney and Associates, we believe in the power and efficiency of well-designed machines. Utilizing one of our numerous customizable cartoners, we can create an automated cartoning and assembly line for your product and get it packaged and shipped out in a fraction of the time.